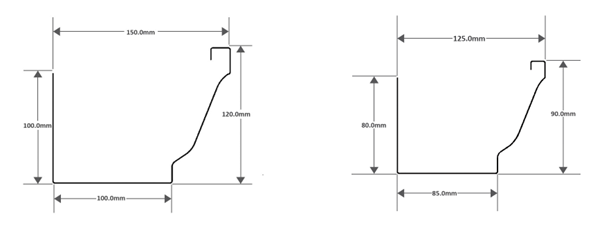

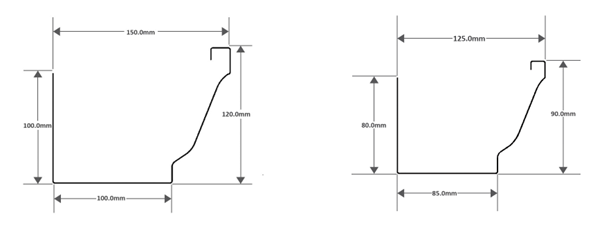

Our RainGain range is a popular range of Aluminium and Aluminium-Zinc gutters. The design is typical of the OGEE gutter system that incorporates a double curve with the shape of an elongated ‘S’. In South Africa, the most commonly used gutter sizes are the 125mm residential and 150mm industrial gutters (measured front to back at the widest point). RainGain gutters have almost twice the water carrying capacity of their half-round competitors of the same width, and can be rolled in a wide range of colours to match any architectural design.

| Gutter Body |  |

| Application | Fixed to the roof structure, through the fascia with Aluminium gutter brackets at 600mm centres. |

| Size | 125mm / 150mm RainGain brackets |

| Material | C1S ALUM |

| 125 Code | GU0400 GU0450 |

| 150 Code | GU0405 GU0455 |

| Gutter Brackets |

|

| Application | Fixed to the roof structure, through the fascia with fasteners appropriate to the application. |

| Size | 125mm / 150mm RainGain brackets |

| Material | C1S ALUM |

| 125 Code | GU0460 |

| 150 Code | GU0465 |

| Stop Ends |

|

| Application | Fixed to the ends of the gutter body with Aluminium sealed rivets or crimped onto the gutter. |

| Size | 125mm / 150mm Left & right Aluminium gutter stop |

| Material | C1S AZ SS C1S ALUM |

| 125 Code | GU0410 GU0415 GU0470 GU0475 |

| 150 Code | GU0420 GU0425 GU0480 GU0485 |

| Mitres - 90° |

|

| Application | Fixed to the gutter body with Aluminium sealed rivets and silicone. |

| Size | 125mm / 150mm Inside corner mitre-90° |

| Material | C1S AZ SS C1S ALUM |

| 125 Code | GU0430 GU0490 |

| 150 Code | GU0440 GU0500 |

| Straight Downpipe |

|

| Application | Fixed to the wall with downpipe cleats at maximum centres of 1800mm. Downpipe fixed to cleats & downpipe bends with Aluminium sealed rivets. Cleats fixed to the wall with nail in anchors. |

| Size | 100 x 75mm downpipes 2.45m stock lengths |

| Material | C1S AZ SS C1S ALUM |

| Code | DP0200 DP0250 |

| Downpipe with Shoe |

|

| Application | Fixed to the wall with downpipe cleats at maximum centres of 1800mm. Downpipe fixed to cleats & downpipe bends with Aluminium sealed rivets. Cleats fixed to the wall with nail in anchors. |

| Size | 100 x 75mm downpipes 2.45m stock lengths |

| Material | C1S AZ SS C1S ALUM |

| Code | DP0205 DP0255 |

| Downpipe with Cleats |

|

| Application | Fixed to the downpipe with Aluminium sealed rivets, and to the wall with nail in anchors. |

| Size | |

| Material | C1S AZ SS C1S ALUM |

| Code | DP0210 DP0260 |

| A Bends - A1 |

|

| Application | Fixed with Aluminium sealed rivets to gutter & downpipe components. |

| Size | 75° / 90° |

| Material | C1S AZ SS C1S ALUM |

| Code | DP0215 DP0220 DP0265 DP0270 |

| A Bends - A2 |

|

| Application | Fixed with Aluminium sealed rivets to gutter & downpipe components. The A2 A bend can also be used as a downpipe shoe. A-Bends are bent around the wide flange of the downpipe (A2 = seam on the outside of the bend). |

| Size | 75° / 90° |

| Material | C1S AZ SS C1S ALUM |

| Code | DP0225 DP0230 DP0275 DP0280 |

| B Bends |

|

| Application | Fixed with Aluminium sealed rivets to downpipe components. B-Bends are bent around the narrow flange of the downpipe. Seams always face the wall, out of sight. |

| Size | 75° / 90° |

| Material | C1S AZ SS C1S ALUM |

| Code | DP0235 DP0240 DP0285 DP0290 |

| Offsets |

|

| Application | Fixed with Aluminium sealed rivets to gutter & downpipe components. |

| Size | Offset 100mm |

| Material | C1S AZ SS C1S ALUM |

| Code | DP0245 DP0295 |

|

1. Measure around the building

|

|

|

2. Assemble pre-cut gutter lengths on the ground Connect the two gutter sections by cutting back 100mm on the front lip of the gutter & slide the second piece inside (in the direction that water needs to shed). |

|

|

3. Install gutter brackets With the gutter assembly complete, space out the gutter brackets inside the gutter, based on the truss/rafter spacing and add one bracket between these (total distance between brackets should be 500- 700mm). |

|

|

4. Assemble stop ends Apply stop-ends to the gutter lengths where you require the flow of water to stop. |

|

|

5. Cut holes for the downpipes in the gutter Using a piece of the downpipe, trace the outline of the downpipe on the bottom of the gutter where you want the section installed. |

|

|

6. Line-up gutter To ensure a straight line when hanging a gutter, make use of a nail & string line/chalk line along the edge of the roof to serve as a guide when installing the gutter. |

|

|

7. Hang the gutter Slide the gutter (with brackets inside) in place, to line up with the pre-marked line. |

|